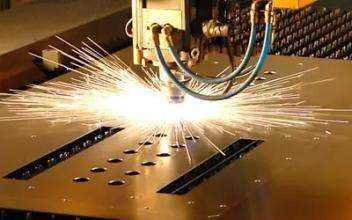

Machining accuracy error of laser cutting machine

The processing effect of the laser cutting machine is actually very good, so we can use the laser cutting machine for processing operation. However, after the laser cutting machine is used for a period of time, many factors will cause the processing accuracy of the laser cutting machine to decline. Do you know about the processing accuracy error of the laser cutting machine?

The machining accuracy of laser cutting machine is the main specification parameter used to measure the quality of machine tools in the industry at present. In the process of equipment sales, the sales personnel will have a detailed description of the processing functions of the products. Among them, the processing accuracy of laser cutting machines is mostly within the error range of 0.5mm. Of course, a small number of manufacturers provide laser cutting machines with processing accuracy up to 0.3mm error In terms of cutting accuracy, there is still a certain error range, which is what we call the processing standard.

The processing of laser cutting machine is based on the planning of enterprise cutting drawings, and the general cutting drawings of parts have clearly marked public service areas and values. Considering that the positions of service belts of cutting parts cannot be common, in the practical cutting process, it may be necessary to eliminate the above service areas through various technological methods.

In the programming of laser cutting machine, if the methods and skills are used properly, it is of great significance to ensure and improve the machining accuracy of CNC machine tools. Many dimensions of parts are marked with public service, and the orientation of public service belt is impossible to be common. However, the NC program is usually compiled according to the outline of the part, that is, according to the basic dimension of the part. In this way, even if the accuracy of CNC machine tool is very high, the parts processed may not meet the requirements of its standard service.

In terms of processing methods and methods, the radius compensation method can be first considered to compensate the influence of cutting public service. This kind of method is relatively simple for practical cutting operation. The detailed idea is still to program and perform in the control system of laser cutting machine according to the basic dimension of the parts, that is, calculate and program according to the basic dimension of the parts, use the same turning tool to process all external circles, and Different tool radius compensation values should be selected when the dimensions of service belt orientation are different. In this way, we must know the radius of the tool tip first (the machining track of this part is parallel to the x-axis and z-axis, so we don't need to know the radius of the tool tip arc), so it is not convenient to use and can only be applied to some CNC systems.

The above-mentioned processing methods may be relatively messy in the later cutting operation. It is also feasible to modify the size of the cutting pieces according to the requirements of the drawings in the early stage of cutting, so as to eliminate the influence of the public service area. The detailed idea is to change the basic scale and the orientation of the public service zone; In the aspect of performance, it is to adjust the basic dimension and the orientation of service belt on the premise that the limit dimension of parts remains unchanged.

Generally, it is adjusted according to the symmetrical public service belt. Programming according to the adjusted basic scale, so that the same turning tool and the same tool compensation value (in this case, the machining track is parallel to the x-axis and z-axis, so the machining accuracy can be ensured. Of course, if the parts have to finish machining (such as finish grinding), in order to ensure sufficient grinding allowance, the basic dimension can also be slightly increased (at this time, the utility belt will be asymmetric).

Source: Jiangmen laser cutting http://www.jmdxbxg.com/index.html

-

11-14

What are the functional features of stainless steel plate?

Analysis of functional characteristics of stainless steel plate: 1. Corrosion resistant stainless steel plate has similar ability to resist general corrosion as unstable NiCr 304. Long time heating in the temperature scale of chromium carbide may affect the corrosion resistance of alloys 321 and 347 in harsh corrosive media. It is mainly used at high temperature, which requires strong sensitization resistance to prevent intergranular corrosion at lower temperature. 2. High temperature oxidation

-

11-14

Four factors affecting the coating of stainless steel plate

There are four kinds of factors that affect the coating of stainless steel plate: first, the connotative factor of stainless steel plate. What we all know is that the low nickel content in stainless steel makes the passivation function of stainless steel low. Therefore, the content of martensite and chromium and nickel in stainless steel has great influence on the passivation function of stainless steel plate. Second, stainless steel plate uses the medium in the environment. In thermodynamics, t

-

11-14

What are the materials that cannot be cut by fiber laser cutting machine?

People who have a certain understanding of the fiber laser cutting machine should know that its use scale is very wide, and the cutting effect is also very good. But fiber laser cutting machine is not what kind of material can be cut, there are some materials on the fiber laser cutting machine damage is relatively large, so can not use the fiber laser cutting machine to cut. Although the fiber laser cutting machine has many excellent characteristics, it is not invincible. There are still many da

-

11-14

What kinds of laser cutting machines are there?

According to the different laser generators, laser cutting machines on the market can be roughly divided into three types: CO2 laser cutting machine, YAG (solid state) laser cutting machine and optical fiber laser cutting machine. One: CO2 laser cutting machine, CO2 laser cutting machine can stably cut carbon steel within 20 mm, stainless steel within 10 mm, and aluminum alloy below 8 mm. The wavelength of CO2 laser is 10.6um, which is easy to be absorbed by nonmetallic materials. It can cut woo